+91- 6379604589

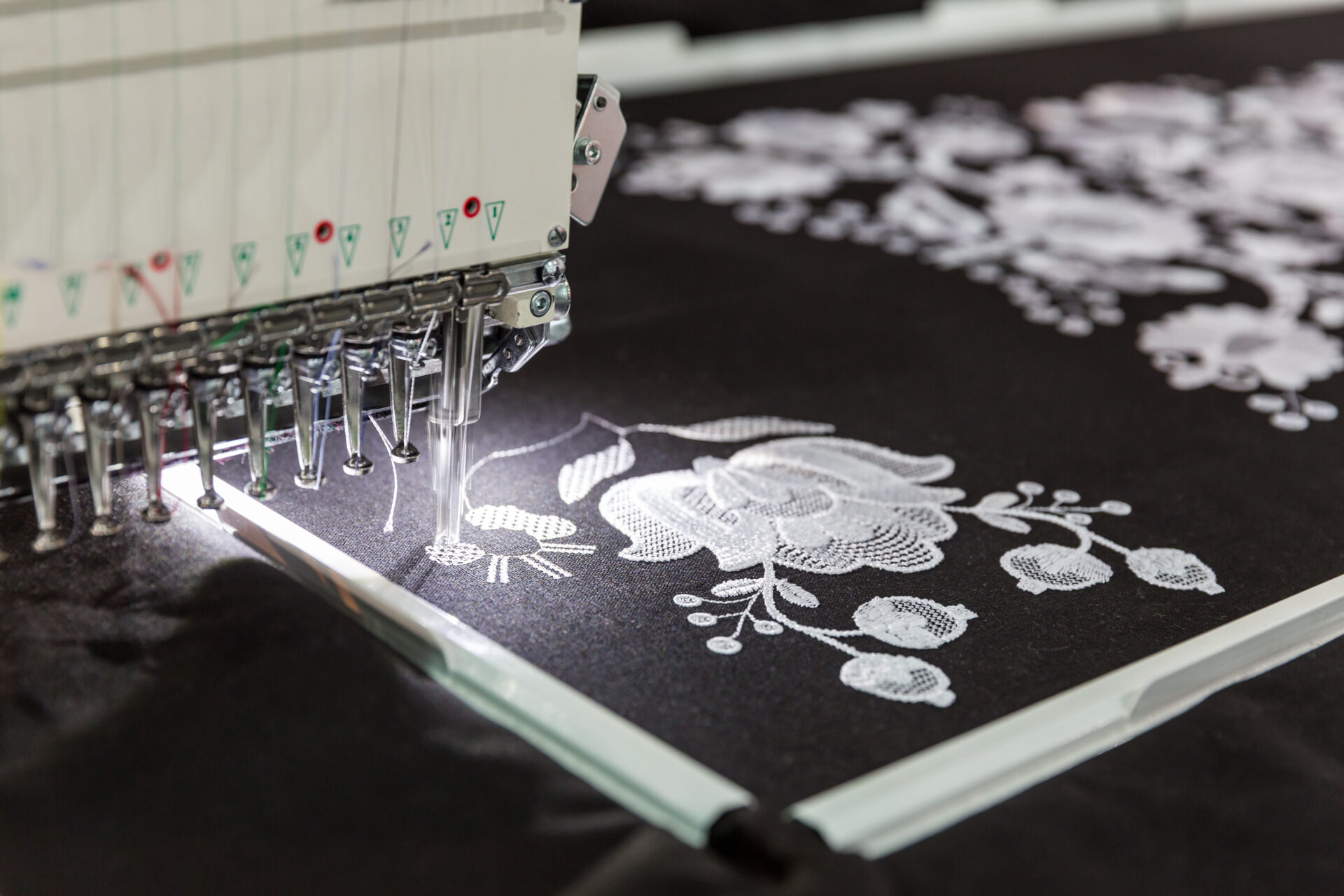

At G SQUARE INTERNATIONAL, we believe that strong infrastructure is the backbone of consistent quality and timely delivery. Our vertically integrated setup enables us to maintain complete control over every stage of production — from raw material sourcing to final packing.

We continuously invest in modern machinery, efficient layouts, and skilled labor to deliver exceptional products at scale.